Die Casting

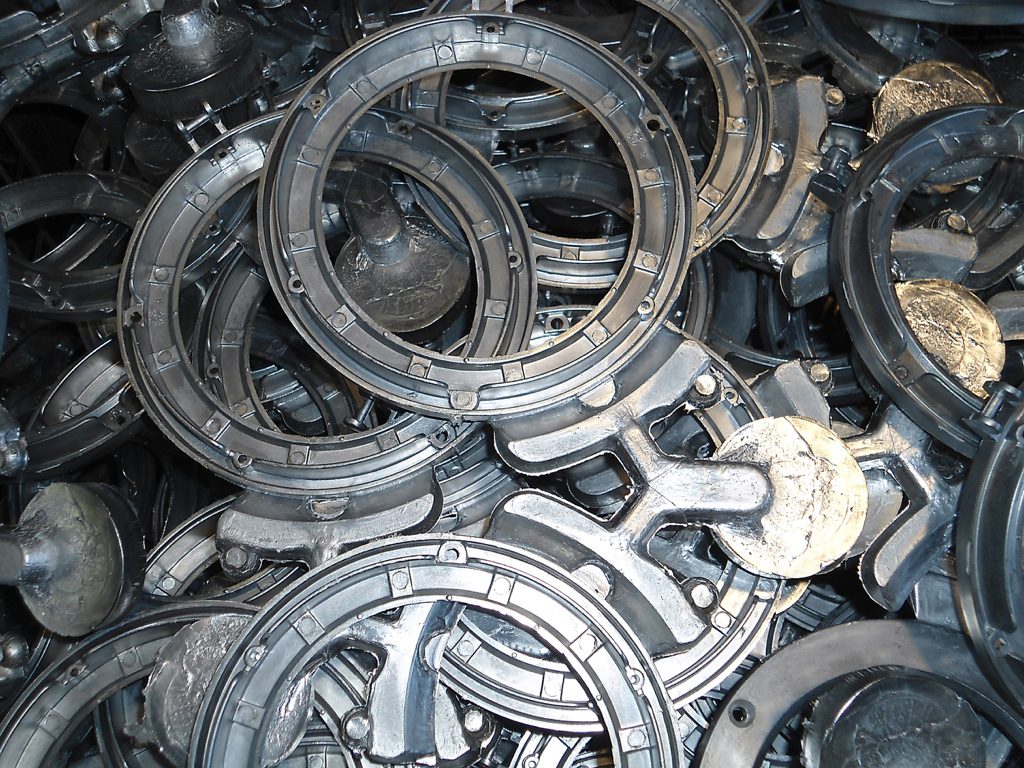

In 1999 our company opened a new die-casting department in response to a sudden change in market demands, proof of the fact that we are always attentive and sensitive to customer needs.

Die Casting

In 1999 our company opened a new die-casting department in response to a sudden change in market demands, proof of the fact that we are always attentive and sensitive to customer needs.

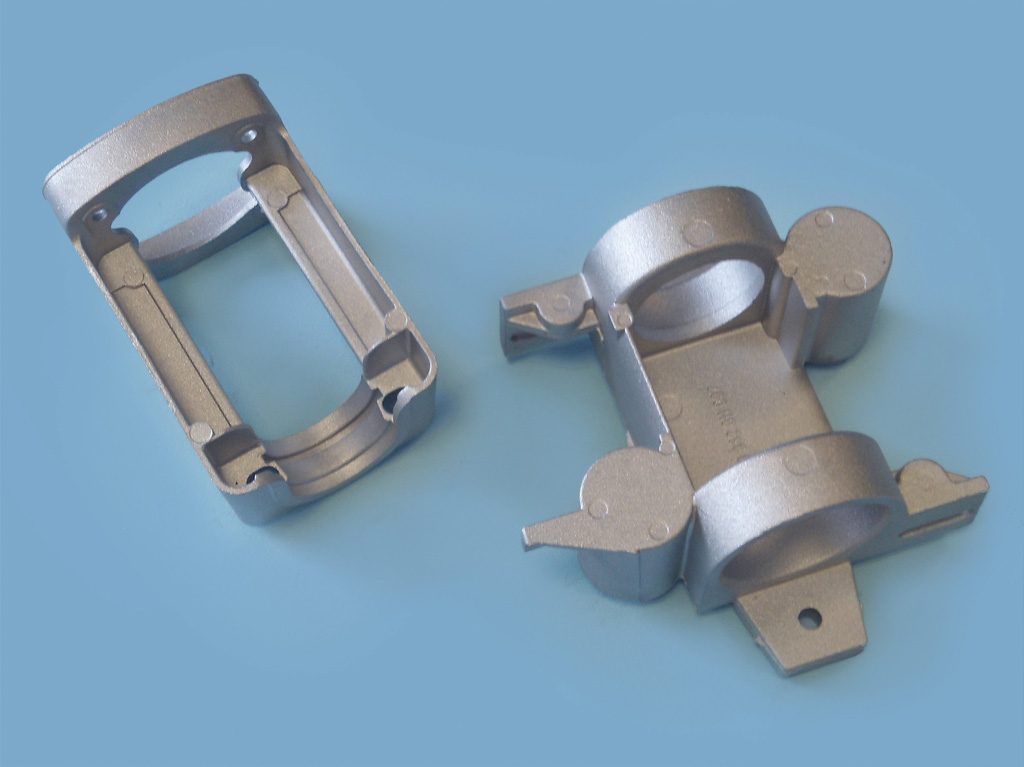

This department too, like the shell casting department, has electrical crucible melting and holding ovens, which offer great versatility in the use of various aluminium alloys, providing a higher quality weld pool as well as a generally better working environment and improved environmental friendliness.

We currently have three machines, 200t, 250t and 360t respectively, two of which are fully automated by plc and controlled by robots. All the machines are working at full capacity.

Research in the area of innovations has introduced us to production with 4.0 technology. Therefore, we have purchased a new high-pressure die-casting machine connecting its integrated system with our production office. This allows us to see the layout of the Island and the current production status, and also to analyse process data for the on-going monitoring of the production unit.